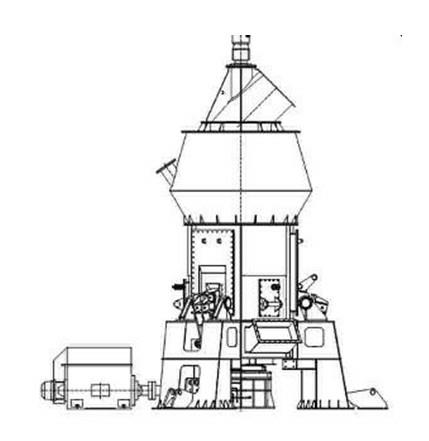

Vertical grinding mill Characters:

● Small abrasion, low consumption and long life. Not direct contact between millstone disc. Rollers and liner are made of high abrasion-resistant material.

● Reliable operation and easy maintenance. The rollers can be taken out of the mill. For those large machine with four rollers, when one or two rollers in symmetric position is repaired, the other two rollers can work as usual, by which it can make 60% to 70% normal capacity, not affection or small affection to the entire production line.

● Costs-effective, save investment. Being simple system and vertical structure, it can be installed open-air, save construction costs

● Small vibration, low noise, no flying dust.

●High efficiency, saving energy. Compared with ball mill system, it can save electricity 30 ~ 50%, being with a large proportion of outer loop, the system power consumption can reduce 20%.

●High proportion of fine powder, high precision and high efficiency separate. It is suitable for the production of ultrafine powders.

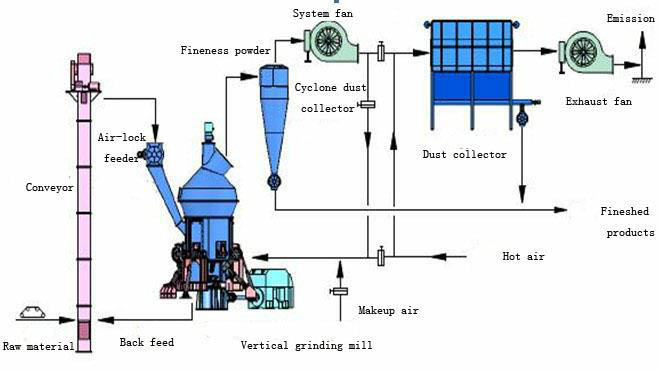

Working principle:

Material bed is pulverized repeatedly by rolling of the rollers. Substandard thick powder will be back feed and re-grinded.

High production capability, Ultrafine powder!!!